Cooling Jacket

Space suits needs internal cooling to allow astronauts to withstand high temperatures occurring during sun exposure in open space. A Canadian company has developed a simple concept which was identified by Grado Zero Espace within the framework of the Technology Transfer Programme of the European Space Agency.

50 meters of plastic tubing, 2 mm wide are needed to construct the internal cooling circuit. This probably gives you an idea of the complex manual labour required to make a jacket structure in this way. The whole of an italian Summer 2001 fashion collection was built around the 'Cooling System', from the choiced fabrics, to the complex tubing details which echoes throughout the entire collection. Grado Zero Espace is addressing its efforts to improve our standard of living.

I.O.W

(Intelligent Object to Wear)

This jacket, thanks to the research by Grado Zero Espace, uses the latest technology from some of the most innovative deep sea diving equipment. The I.O.W. is a motorbike jacket with an internal heating mechanism (produced by a specialist English firm). This garment is the first portable heating system for motorbikers. This sophisticated device can be connected directly to a motorbike or a scooter, and can monitor body temperatures in 4 different areas of the torso (arms, chest, back and shoulders) and regulate those temperatures accordingly. The philosophy of this garment follows the research for solutions which can improve the quality of life, whatever the occasion.

Inside the jacket lining is a computerized microprocessor with hard disk (no bigger than a packet of cigarrettes) which controls the body temperature over a series of electric heating pads.

The five pads, (located at the lower back, the shoulders, the chest and the arms) can be individually monitored to desired temperatures. It is the ingenuity of these pads that makes this temperature management system different from other previous attempts at heating systems in jackets. These soft body forming pads heat in this following manner.

A thin strip of metal is vacuum sealed between two layers of gel and then covered in KEVLAR tm, (bullet proof fabric used by Police/Army) On this thin strip of metal is a chip that sends impulses to the computer relaying messages on the internal body heat inside the jacket. The special aspect of this gel is that it diffuses the heat rapidly to the body. When the pad temperature reaches the 'preset level', the power will tail off until required again. This prevents over heating and perspiring. The temperatures can be adjusted by a software available on a CD that can be used on almost any PC.

The jacket, via a short cable, is attatched to a well designed leather pouch that houses a 12 volt supply . From this pouch runs a cable to the bike. By plugging in the cable to the bike you start the heating system. When you unplug the cable, (which folds neatly into the pouch) the batteries which have been charged by the bike's engine give you up to one hour of heating power.The microprocessor is shock resistant.

MotoGP AIS (Anatomic Intercooler System)

Grado Zero Espace, together with Spidi and its research centre Safety Lab, present a new anatomic cooling system developed for motorcycling that Sete Gibernau will wear during the Qatar MotoGP race on 3 October 2004.

Maintaining the rider cool inside the suit and managing to keep his body temperature low even at high environmental temperatures:

these are the whys the AIS (Anatomic Intercooler System) is born for. The AIS is an anatomic cooling system developed by Grado Zero espace and Spidi for Sete Gibernau and for what is going to be the hottest race of the year: the Qatar GP in Losail. The AIS will be integrated in the usual Setes racing suit guaranteeing him a better comfort and thus improving the rider safety.

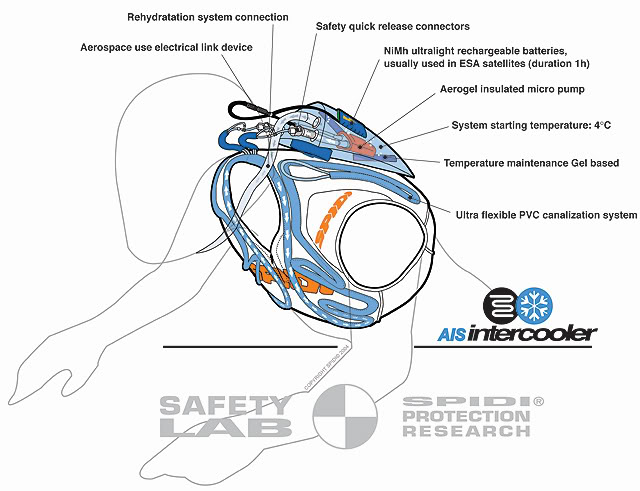

(Scheme of the Anatomic Intercooler System)

With AIS, Spidi technicians transferred to motorcycling a technology originally developed by ESA (European Space Agency) and Grado Zero Espace research centre: a personal cooling system technology previously used in Formula 1 and aerospace ambit that no one imaged could have been transferred to a motorcycle racing suit.

In this sense, AIS represents the realization of a collaboration project between the Spidi Safety Lab, who translated into the motorcycle racing world a Grado Zero Espace/TTP (Technology Transfer Programme) idea that was already applied in other fields.

"By far, the most difficult thing was to integrate all the AIS vital components together with the anatomy of the suit, because we could just not compromise on the original safety and fitting of Setes suit. Its been tough, but in the end I can say we are really satisfied by the result", explains Lorenzo Faggionato, Spidi racing developer in chief.

The cooling system is based on icy gel cooled water running through a serpentine that is placed on chest and back by a custom made anatomic vest to be worn under the suit surface, while an ultra light battery and a micro pump are inserted inside the suit hump. Check this link for a more detailed profile.

All these elements have been integrated so well into the original suit structure that Sete will be able to drink while racing thanks to a special bag filled by rehydrating drink also integrated in the hump and linked with the helmet. A rehydrating system that Sete successfully already used last year at Sepang for the Malaysian GP.

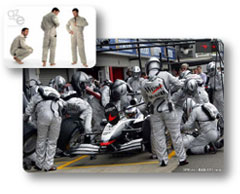

Courtesy by West McLaren Mercedes

F1 McLaren's cooling coveralls

In collaboration with the European Space Agency ( the transfer technology programme directed by Pierre Brisson ) and Med-Eng Systems Inc. designed and produced an hyper-technical overall for the big fashion producer "Hugo Boss" destined for use by McLaren's Formula One mechanics. The design of the coveralls is by Mauro Taliani.